Why Use Royal Purple? Why Use Royal Purple?

RP's Unique Performance Advantages

Superior Technology Creates Superior Products

Royal Purple's proprietary additive technologies, such as Synerlec, enable its products to outperform leading synthetic and conventional lubricants. These unique chemistries strengthen the base oil for unmatched performance. They also create an ionic bond that adheres to metal parts for continuous protection.

High Film Strength Improves Performance

The film strength of a lubricant is its inherent ability to withstand the effects of load, speed and temperature without breaking down or rupturing, thus enabling the lubricant to maintain an unbroken film between lubricated surfaces under operating conditions. Royal Purple's film strength is up to 400% stronger than other oils. A high film strength improves combustion to create more power, better fuel economy and reduced emissions. High film strength also dramatically reduces wear.

According to the editors of Hot Rod Magazine, "We've torn down some of our dyno engines that have been seriously abused, but with Royal P(urple) in the pan, the bearings have looked new."

Royal Purple actually improves the condition of metal surfaces by remaining long after pressure would have been squeezed out ordinary lubricants. Royal Purple responds to increased pressure with increased viscosity. Take a look at the following photos:

A new bearing surface appears smooth until magnified 1500X.

The same bearing surface roughened after using a leading synthetic oil.

The same bearing surface after using Royal Purple.

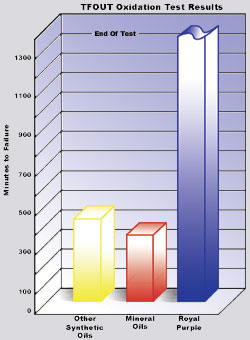

Lubricants often have a limited service life due to oxidation which reduces oil's ability to lubricate. Oil's ability to resist oxidation is measured by the ASTM's rigorous Thin Film Oxidation Uptake Test (TFOUT). The test is so severe that it lasts only 1300 minutes. Royal Purple not only surpasses leading mineral- an synthetic-based oils in the test, it also outlasts the duration of the test.

Royal Purple's superior oxidation stability enable oil changes to be extended up to 12,000 miles or more depending on the equipment. Extending oil change intervals save you time and money. It also reduces the impact on the environment by reducing the amount of oil that has to be produced and disposed of.

|